-

Machinebeveiliging

Machinebeveiliging

Axelent is een van de toonaangevende fabrikanten van machineafschermingen op de markt. Het complete systeem dat wij leveren voldoet aan de huidige richtlijnen en normen.

-

Magazijn

Axelent is een van de toonaangevende merken van gaaspanelen voor industrie- en magazijnomgevingen op de markt

Axelent is een van de toonaangevende merken van gaaspanelen voor industrie- en magazijnomgevingen op de markt. Onze producten en systemen zorgen voor flexibele en snel passende oplossingen in alle fasen van het proces, van het maken van de tekening tot de uiteindelijke montage van het product.

Scheidingswanden en kooioplossingen

Voorkomen van vallende goederen - palletstellingen

Valbeveiligings-systeem

Mesh rekken

-

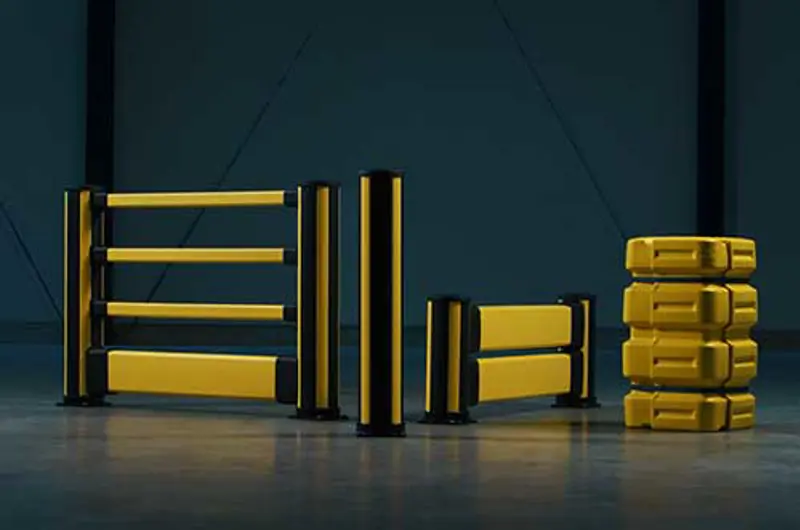

Aanrijdbeveiliging

Aanrijdbeveiliging

Dit is ons assortiment aanrijdbeveiligingsproducten. Wij hebben alles van bolders tot veiligheidsbarrières voor voetgangers en meer.

-

Kabelgoten

X-Tray Cable Trays - A Premium Brand from start to finish

X-Tray is het kabelmanagementsysteem van Axelent. Het heeft het grootste assortiment op de markt, zowel qua materiaal als functie. Sinds 1 september 2022 wordt X-Tray geproduceerd, opgeslagen en verkocht via Axelent Wire Tray.